Technical Parameters

| Platform | Aviation cast aluminum |

| Dimensions and weight | 826*793*835(mm);175kg |

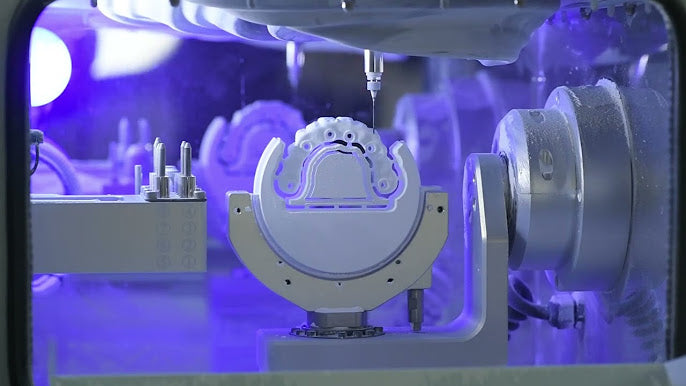

| Processing methods | Dry milling |

| Number of tools | 10 |

| Automatic disc changer | 8 |

| Dust-proof | One-piece silicone, good dust-proof airtightness |

| Fixture Type | C-type fixture/C-type secondary fixture |

| Processing material thickness | 10-30mm |

| Processing material | Zirconia, resin, wax, PMMA, peek and other soft materials |

| Processing type | Crowns, bridges, implant bridges, veneers, inlays, open crowns, temporary crowns, etc. |

| Typesetting CAM software | Open |

| Rotation axis angle | Axis:±360°;Baxis:±28° |

| Motor | Servo motor |

| Function | Intelligent fixture recognition function Tool life management Working Status Indicator Safety door Ion wind cleaning function Vertical processing |

| Spindle | Air cooled MAX:60000RPM AC 500W 4mm closet |

| Barometric pressure | ≥6Bar |

| Power supply | Simplex AC 220V 50/60Hz 8A 1.8KW |

| Processing time | Single crown <17min; Implant bridge <3h |

| Base | Optional |

Request More Information About the AMD500DCs Milling Machine

If you would like to receive further details about the AMD500DCs Milling Machine or have specific questions regarding its features, performance, or purchasing options, please fill out the form below. Our expert team will get back to you as soon as possible with all the information you need.

We are here to help you choose the best milling machine solution for your needs!